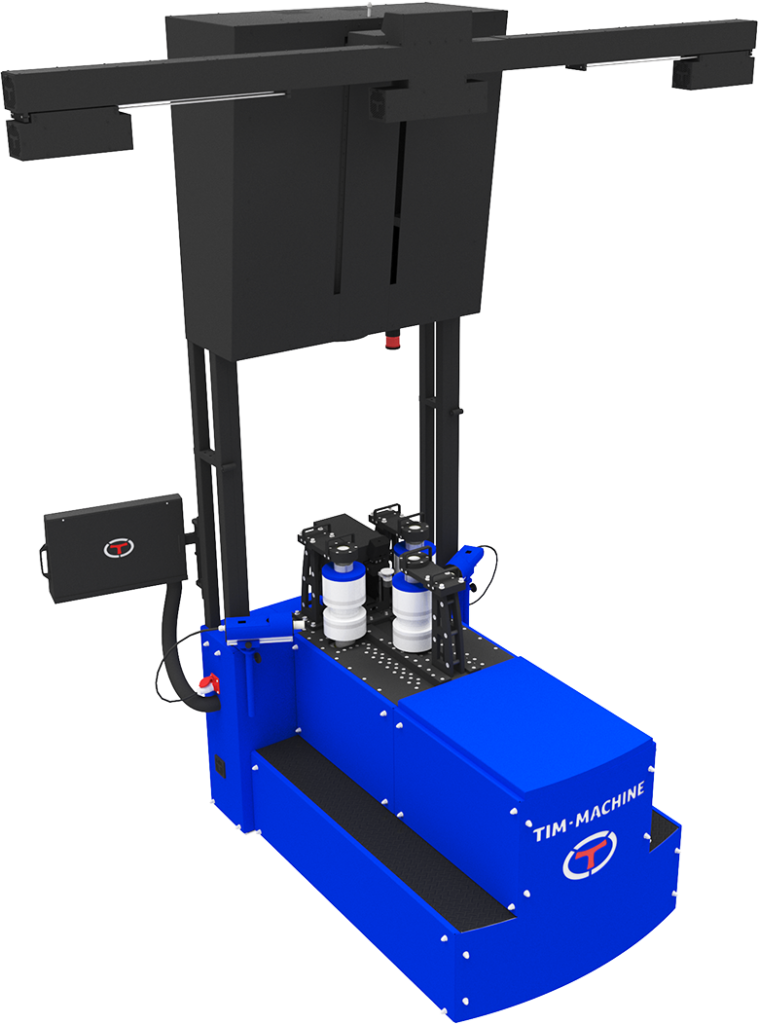

TIM-MACHINE

MODEL M

Select model

HOME » PROFILE BENDING MACHINES » MODEL M SELECTION

MANUAL

Manual controled machine

STANDARD EQUIPMENT

ADDITIONAL EQUIPMENT

SOFTWARE FOR ARCH BENDING

ADDITIONAL INFO

MACHINE CAPACITY

TECHNOLOGY DESCRIPTION

ADVANTAGES

VIDEO

STANDARD EQUIPMENT

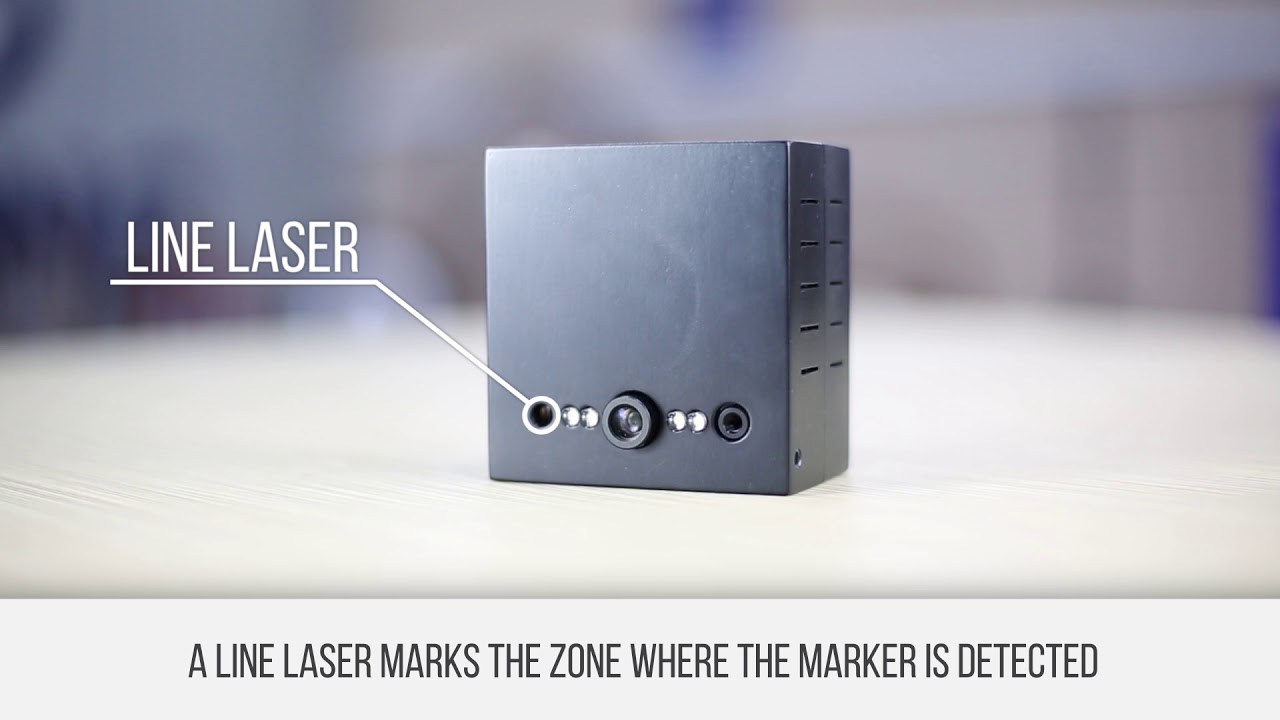

Laser device with thermal camera

- Laser device with thermal camera is an optical device of latest generation which contains special thermal sensor that measures current temperature of a profile during bending. NEW

- Laser device with thermal camera has a function to detect a marker on the middle of a profile so that an arch can be symmetrical on both left and right side at the end of bending process.

- Laser device with thermal camera enable precise measuring of temperature of a PVC profile during bending process. Information about current temperature of a PVC profile during bending is very important because the program based on this information can automatically adjust and correct bending process that was started.

- Laser device with thermal camera contains a display located on the back side of the device on which an operator can easily notice detected marker on the middle of a profile.

- Laser device with thermal camera contains gyroscope which determines an angle ie. inclination of laser device in regard to a profile. Information about inclination of a laser device in regard to a profile is very useful during positioning of the laser device in regard to the profile.

- Laser device with thermal camera contains a sensor which measures a distance between a laser and a profile which makes positioning of the device in regard to the profile easier.

- Laser device with thermal camera contains a light sensor which clearly marks the reading zone of the laser device with red horizontal line on a profile.

ADDITIONAL EQUIPMENT

Remote control

- Remote control serves as a controlling device of the axles on the bending machine.

- Remote control controls the X rotation movement of the back axles and Y straight movement as well as rotation movement of middle axle on the machine.

- Remote control has a range of around 50 m.

- Remote control is very useful because it makes work significantly easier to a machine operator especially in a situation when a long profile is inserted in the tools.

- Remote control is practical in a situation when after completed bending process bent profile is removed out of the machine.

- Remote control replaces four green buttons which are located on the control board of the machine.

- Remote control has a safety STOP button which enables the machine operator to immediately stops the bending process from a safe distance in case of an unforseen or dangerous situation.

NFC device

- NFC device serves as a quick and easy way for an operator with a coded card to sign-in and signout to a machine, by which greater program safety as well as safety of all the data on it is achieved.

- NFC device enables access to bending corrections which are the most important data in the machine program exclusively to a machine operator via coded card.

- NFC device enables that one operator can at the same time have access to main program as well as to bending corrections.

- NFC device uses application which doesn’t allow another operator to login into a machine program if he doesn’t have his coded card or password. If a machine operator forgets his card he can always login via matching password.

- NFC device is installed on the inner side of a lower machine’s cabinet.

Automatic pneumatic platform for laser and encoder

- Automatic pneumatic platform is a device which serves to carry the encoder and the laser device and it is placed on the middle of the control board right behind the back machine axles. NEW

- Automatic pneumatic platform has a direct communication with a machine’s computer so that an operator has a possibility to position the platform in regard to a profile in following 3 ways: 1. First method is for a pneumatic platform to be positioned on its own on the required height based on previously selected profile which in the program has already saved predefined height position of the platform in regard to the profile. 2. Second method is to position platform manually with 4 buttons on the monitor. 3. Third method is to position platform manually with 2 buttons placed on the right side of the platform.

- Automatic pneumatic platform enables faster, more precise and easier process of positioning of the platform before bending initiation to an operator.

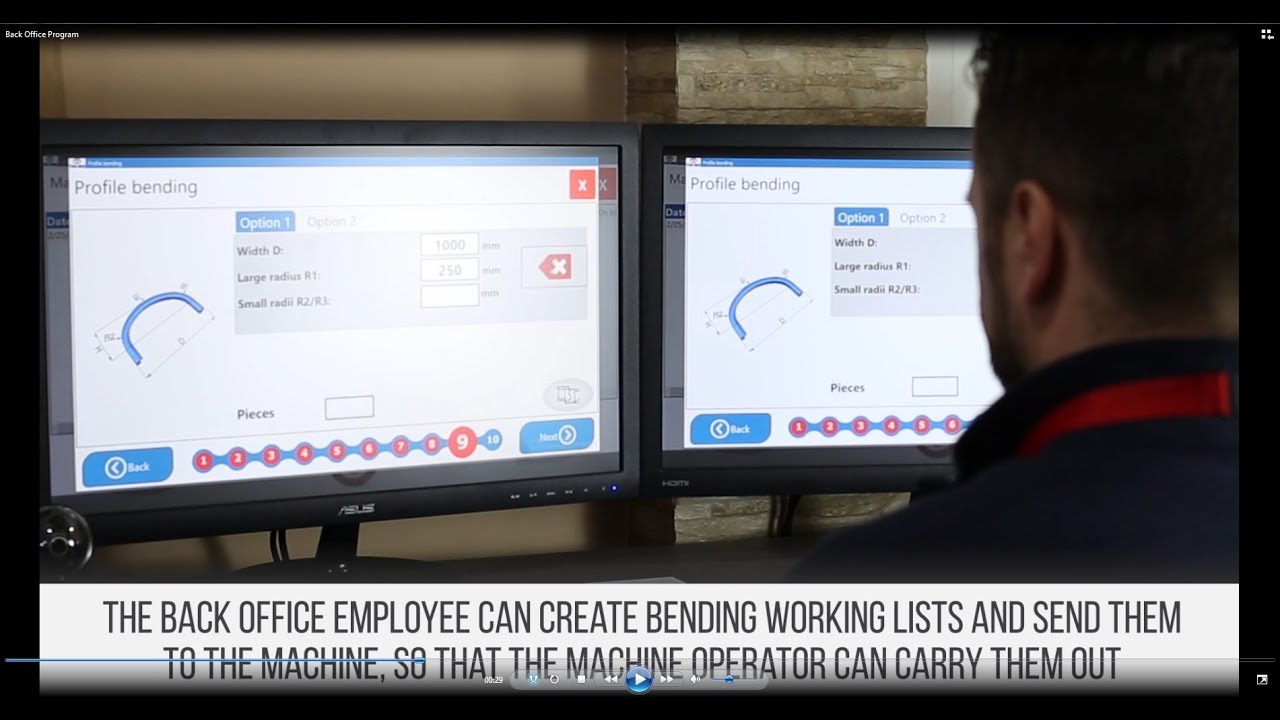

Program for creating work orders for bending from an office

- Program for creating working orders for bending, enables an operator who works in an office a complete online control and communication with bending machine. Office operator with the help of the program has an option to create working lists for bending and after that to send directly from his/her own office computer the tasks in a form of a working list to bending machine that await to be executed. By using this program, work for a machine operator is made significantly easier; it removes possibility of miscommunication between an office and production. Office operator has a possibility to observe visually and oversee via 3D cameras the machine in real time. Office operator can at any time keep track of the phases from working list the machine operator managed to execute which was previously sent to a bending machine. NEW

Permission to input new profiles into the machine’s program

- Permission to input new profiles into the machine’s program is charged extra and it enables an operator to input without limits and completely independently new profiles into the machine’s program since this option is disabled in the standard equipment package on all machine models. NEW

- Permission to input new profiles into machine’s program enables an operator to independently insert all the necessary parameters as well as desired corrections for each new profile.

- Permission to input new profiles into machine’s program is quite significant and it refers only to the customers who want to make independently new tools for bending profiles after buying the bending machine.

- Additional explanation: Machine buyer will get already inserted parameters for all the tools he ordered from the seller during the acquisition as well as necessary corrections for each tool ie. for each profile. If the buyer after certain period of time wants to order new tools from the seller he needs to know that tools price already includes the costs for inserting all the parameters and corrections for that new tool ie. new profile. However, if the buyer want to make the new tools on his own it is necessary for him to buy the permission to input the new tools and profiles into the machine’s program. If buyer of the machine decides to make new tools on his own, input of new tools and profiles into machine’s program can be done by the seller for an suitable financial fee. Inserting parameters and corrections into the machine’s program by seller also requires certain time and effort so that work is also charged extra to a buyer of the machine.

Program for 3D scanner for scanning of arch patterns

- Program for 3D scanner serves for scanning of arch patterns of both regular and irregular shaped arches. 3D scanner can scan patterns up to 2,5 meters wide. Pattern scanning lasts around 5 seconds. Upon completing the scanning program automatically determines the measurements detected on the pattern as well as all the radii. Based on this data program automatically determines the shape and measurements of the arch that machine needs to bend.

SOFTWARE FOR ARCH BENDING

SOFTWARE:

CNC 3D 3 in 1

CNC AUTOMATIC

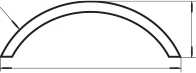

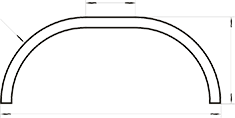

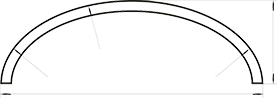

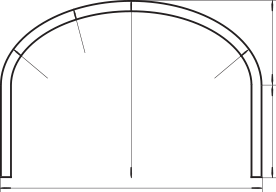

- his machine model bends arch types shown below in 3D 3 in 1 CNC AUTOMATIC mode

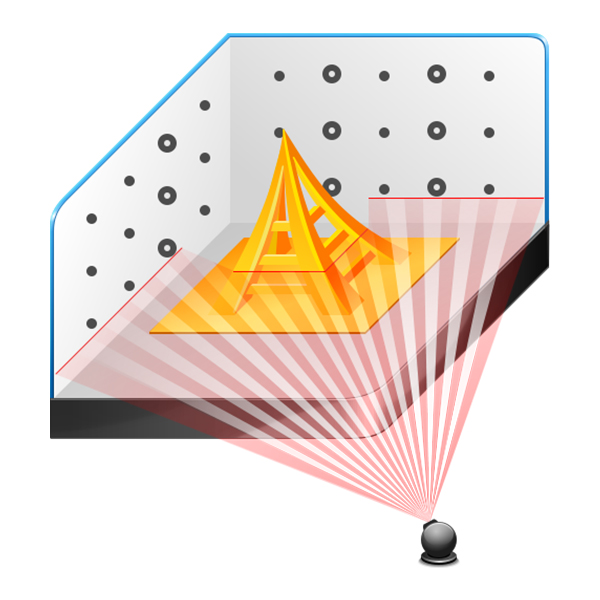

- In this mode the controlling 3D cameras automatically set the profile to its middle point prior to the bending process.

- In this mode the controlling 3D cameras automatically set the profile to its initial bending position prior to the bending process.

- In this mode the computer automatically sets appropriate correction parameter for each new arch, based on the chosen profile, material and bending diameter.

- In this mode the controlling 3D cameras connected with the computer enable automatic profile bending, automatic control and automatic ending of the bending process.

- In this mode the controlled automatic bending is enabled because of the feedback loop between the computer and the controlling 3D cameras.

- In this mode the automatic bending process is corrected and adjusted to the currently measured angle and radius of the arch in each passing, resulting in desired profile bending process according to the preset dimensions of the arch.

- In this mode the profile bending process Is performed completely automatically from the beginning until the end.

- In this mode the controlling 3D cameras measure and control the dimensions of the arch during the bending process on the machine.

- In this mode the machine automatically stops the bending process when the controlling 3D cameras detect that the arch has been bent according to the preset dimensions.

- In the mode the sound notification notifies the operator when there is an obstacle within the dangerous zone around the machine and rollers.

- This mode is equipped with safety 3D camera which automatically halts the bending process when an obstacle is detected in the area around the machine and rollers.

SOFTWARE:

CNC 3D

CNC AUTOMATIC

- This machine model bends arch types shown below in 3D CNC AUTOMATIC mode

- In this mode the controlling 3D cameras automatically set the profile to its middle point prior to the bending process.

- In this mode the controlling 3D cameras automatically set the profile to its initial bending position prior to the bending process.

- In this mode the computer automatically sets appropriate correction parameter for each new arch, based on the chosen profile, material and bending diameter.

- In this mode the controlling 3D cameras connected with the computer enable automatic profile bending, automatic control and automatic ending of the bending process.

- In this mode the controlled automatic bending is enabled because of the feedback loop between the computer and the controlling 3D cameras.

- In this mode the automatic bending process is corrected and adjusted to the currently measured angle and radius of the arch in each passing, resulting in desired profile bending process according to the preset dimensions of the arch.

- In this mode the profile bending process Is performed completely automatically from the beginning until the end.

- In this mode the controlling 3D cameras measure and control the dimensions of the arch during the bending process on the machine.

- In this mode the machine automatically stops the bending process when the controlling 3D cameras detect that the arch has been bent according to the preset dimensions.

- In the mode the sound notification notifies the operator when there is an obstacle within the dangerous zone around the machine and rollers.

- This mode is equipped with safety 3D camera which automatically halts the bending process when an obstacle is detected in the area around the machine and rollers.

SOFTWARE

NC

NC AUTOMATIC

- Shown arch types with two radii are bent on this machine model in two independent automatic NC AUTOMATIC modes.

- In this mode the operator sets the profile prior to the bending process using the buttons on the machine.

- In this mode the machine can set each profile to the initial position prior to the bending process using the PLC.

- In this mode the operator inserts appropriate correction parameter in the software depending on the material and arch dimensions.

- In this mode the correction parameter is inserted and changed every time a new arch is being bent.

- In this mode the PLC is controlling the bending process while the operator has to insert appropriate correction parameter for each new arch.

- In this mode the profile bending process is performed automatically for each radius separately.

- In this mode the operator measures and controls the arch dimensions on the machine during the bending process.

- In this mode the operator ends the bending process when the desired dimensions of the arch are achieved.

ADDITIONAL INFO

- Bending machine is equipped with three 3D controlling cameras which enable smart management and automatic control of the bending process from the beginning to the end. CNC 3D model automatically starts, measures, controls and ends the bending process when the desired dimension of the arch is achieved. NEW PATENT

- Bending machine CNC 3D is equipped with safety 3D camera which automatically halts the bending process when an obstacle is detected in the zone around the machine and the rollers. The CNC 3D machine model has a sound notification for the operator, automatically activated when there is an obstacle within the zone around the machine and the rollers. NEW PATENT

- The feedback loop between 3D cameras and the powerful computer system establishes this 3D system as the most advanced and the most precise profile bending system in the world. Specially designed software, using the most advanced algorithms, automatically manages, controls and safegurds the bending process on the machine. NEW PATENT

- Bending machine CNC 3D is equipped with the laser device which detects the middle point of the arch with millimeter precision. With the laser device the middle point of the arch side shifting error is eliminated, thus achieving absolute symmetry between the left and right side of the arch. NEW PATENT

MACHINE CAPACITY

- Minimum bending radius for certain profiles ranges from 150 to 200 mm

- Bending PVC profiles with steel reinforcement

- Bending unlimited length of a profile

- Unlimited maximum radius of a bent arch

- Bending aluminium and PVC profiles in all four directions

- Bending profiles with original protective foil

- The automated bending process for one profile on the machine lasts from 7 to 8 minutes

- The preparation process includes obligatory sand filling of both aluminium and PVC profiles

- The preparation process includes obligatory sand filling of both aluminium and PVC profiles

- PVC profiles bending is performed utilizing hot air fans

- The bending process and the supervision of the process on the machine is carried out by one operator

- Bending PVC profiles with steel reinforcement is possible only with arches with straight parts longer than 250 mm

- Bending PVC profiles without steel reinforcement

- Bending aluminium profiles with and without thermal brake

- Bending aluminium profiles for aluminium-wood systems

- Bending aluminium curtain wall profiles

- Bending coated, anodized, laminated and colored profiles

- Bending profiles with chambers reinforced with glass fibers

- Bending industrial AL and steel profiles, maximum dimensions 80 x 80 mm, wall thickness 4 mm

TECHNOLOGY DESCRIPTION

- The machine is equipped with two controlling 3D cameras which manage and control the bending process NEW PATENT

- The machine is equipped with safety 3D camera which detects obstacles in the area around the machine and rollers NEW PATENT

- The machine is equipped with a laser device for obtaining symmetrical left and right side of the arch NEW PATENT

- The machine automatically detects and controls the angle of the bent profile during the process NEW PATENT

- The machine automatically measures and controls width and height of the arch during the process NEW PATENT

- The machine automatically stops the bending process when an obstacle is detected in the area around the machine NEW PATENT

- Prior to the bending process the machine automatically positions the profile to the middle of its total length NEW PATENT

- The machine automatically corrects the error of the middle point of the arch during the bending process NEW PATENT

- Machine automatically detects width of the profile prior to the bending process NEW PATENT

- The machine automatically detects total length of the profile prior to the bending process NEW PATENT

- The machine automatically detects and distinguishes the shape of the profile that is being bent NEW PATENT

- The machine automatically detects type of the material that is being bent NEW PATENT

- The machine automatically adjusts the bending process depending on the material that is being bent NEW PATENT

- The machine automatically detects and controls radius of the bent profile during the bending process PATENT

- Machine can be controlled via other computers regardless of the location NEW PATENT

- Machine can automatically bend arches with one, two or three radii in one process

- The machine automatically activates the heating device and sets the temperature for the PVC profile heating during the bending process

- The machine automatically detects and controls the profile during the bending process

- The machine automatically detects the position of the profile during the bending process

- The machine automatically sets the profile to the initial position prior to the bending process

- The machine automatically sets the profile to the desired position prior to and during the bending process

- The machine automatically detects the elongation of the profile and adjusts the bending process accordingly

- The machine automatically measures current length of the arch part during the bending process

- The machine automatically controls and regulates the rotation speed of the rollers

- The machine automatically detects and monitors the position of the rollers during the bending process

- The machine automatically ends the bending process when the predetermined dimensions of the arch are achieved

- The machine is equipped with the LED lamp for illuminating the area of the bending zone

- The machine is supplied with the floor holders for supporting long profiles

- The machine can be connected with other computers for the purposes of data transfer

- Machine has a sound notification for the operator when there is an obstacle within the dangerous area around the machine and rollers.

- The machine requires 30 to 50 square meters area with minimum ceiling 3.65 m

ADVANTAGES

What separate us from our competition

- High-precision 3D cameras control and monitor the bending process NEW PATENT

- Detecting the outlines and position of the profile bent on the machine NEW PATENT

- Automatic detection and control of the bent profile angle during the process NEW PATENT

- Automatic measurement of the arch width and height during the bending processNEW PATENT

- Automatically halts the bending process when an obstacle is detected in the area around the machine. NEW PATENT

- Automatic detection of the profile width prior to and during the bending process NEW PATENT

- Automatic detection of the profile total length prior to the bending process NEW PATENT

- Automatic detection of the type of the material bent on the machine NEW PATENT

- Automatic positioning of the profile to the middle point prior to the bending process NEW PATENT

- Controlling the machine and the process via computer from remote location NEW

- Laser device detects the middle point of the arch with millimeter precision thus achieving symmetry between left and right side of the arch NEW PATENT

- Laser device is used for correcting the middle point of the arch error during the bending processNEW PATENT

- Quality bending aluminium and PVC profiles to extremely small radii, from 200 to 300 mm. We achieve high quality with high precision in tool production and huge experience we acquired in this line of work.

- TIM-MACHINE CNC 3D 3 in 1 is the most advanced bending machine for aluminium and PVC profiles in the world since it is the only machine equipped with high precision controlling and safety 3D cameras that manage, control and secure the bending process. Other bending machines do not have nor are they able to have 3D cameras since the application of 3D cameras on the bending machines with three and four rollers is patented in the world, the owner of the patent being the owner of our company.

- TIM-ING CENTAR company was the first company in the world to start bending PVC profiles with and without steel reinforcement using bending machine with three rollers back in 1999. Our competition from Germany and Italy started using our invention and bending technology for PVC profiles on their machines with three rollers in 2012 when our old patent expired (patent: WO2004045833 A1).

VIDEO

Video of the bending machine with 3D cameras!

Watch the bending process of Aluminium and PVC profiles on the most advanced machine in the world controlled via high precision 3D cameras!

Watch the bending process of Aluminium and PVC profiles on the most advanced machine in the world controlled via high precision 3D cameras!

Playlist

9 Videos